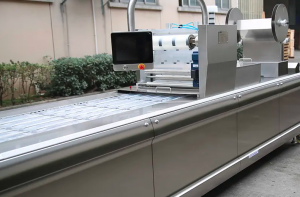

Thermoforming Lub Tshuab Nqus Tsev Ntim Ntim MachineUa si lub luag haujlwm tseem ceeb hauv kev lag luam ntim khoom, kom paub meej tias cov khoom lag luam muaj kev ruaj ntseg thiab kaw tau zoo rau lub txee tshiab. Txhawm rau kom ntseeg tau tias qhov ntev thiab ntev ntawm cov tshuab no, kev tu yog qhov tseem ceeb. Hauv tsab xov xwm no, peb sib tham txog qee cov lus qhia tseem ceeb kom tswj koj lub tshuab ua haujlwm ntim tshuab thermoform.

1. Kev tu tsis tu ncua: kev tu tsis tu ncua yog qhov tseem ceeb kom tiv thaiv cov av tsim av, khib nyiab thiab cov khoom noj ntawm cov khoom siv tshuab. Ua raws li cov lus qhia kev ntxuav, uas yuav suav nrog kev siv tshuaj ntxuav lossis cov kev daws teeb meem tshwj xeeb. Them nyiaj tshwj xeeb rau kev sib khi thiab cov chaw txiav, raws li ib qho seem ntawm cov chaw no yuav cuam tshuam rau qhov zoo ntawm pob. Nco ntsoov ntxuav tag nrho cov khoom kom huv si thiab cia kom qhuav ua ntej siv lub tshuab dua.

2. Lubricating ntawm cov chaw txav ntawm lub tshuab yuav pab txo kev sib txhuam thiab ua haujlwm kom du. Tshawb xyuas cov chaw tsim khoom lag luam cov txheej txheem los txiav txim siab txog lubricant kom zoo thiab ntau zaus ntawm lubrication. Tshaj-lubricuric nyiam av thiab khib nyiab, yog li nco ntsoov thov cov roj nplua nyeem sparingly thiab so tawm ntau dhau.

3. Tshuaj xyuas thiab hloov cov khoom hnav: ntu tshawb xyuas lub tshuab rau txhua cov cim ntawm kev hnav xws li tawg lossis xoob ntsaws ruaj ruaj. Hloov hloov cov khoom puas los sis hnav kom tsis txhob muaj kev puas tsuaj ntxiv rau lub tshuab thiab ua kom lub ntim dav hlau. Khaws cov khoom seem ntawm txhais tes kom txo qis downtime thiab xyuas kom meej tias tsis tshua muaj.

4. Kho lub tshuab ntsuas: tsis tu ncua ntsuas lub tshuab yuav pab saib xyuas nws qhov tseeb nrog rau qhov kub thiab txias, thiab lub sijhawm sib khi. Ua raws li cov chaw tsim khoom cov lus qhia kom muaj tshuab kom zoo. Kev ntsuas hluavtaws tuaj yeem daws cov chaw kub, hloov cov ntsiab lus cua sov, lossis rov ua dua timers.

5.. Tsheb nqaj hlau ua haujlwm: cov neeg ua haujlwm tau raug cob qhia yog qhov tseem ceeb los tswj thiab ua lag luam thermoforming nqus ntim tshuab. Nco ntsoov tias koj lub tshuab ua haujlwm tau paub txog lub tshuab ua haujlwm, cov lus qhia kev nyab xeeb thiab kev saib xyuas cov txheej txheem. Muab cov kev kawm ua ntu zus los hloov kho lawv cov kev paub thiab kom lawv muaj peev xwm txheeb xyuas thiab daws cov teeb meem muaj peev xwm ua raws sijhawm.

6. Ua raws cov lus qhia kom tau siv:Thermoforming Lub Tshuab Nqus Tsev Ntim Ntim Machinemuaj cov lus qhia tshwj xeeb rau kev siv muab los ntawm cov khw. Ua raws li cov lus qhia no kom tsis txhob muaj overloading lub tshuab thiab ua rau hnav ntau dhau. Tsis txhob tshaj tus lej pom zoo tshaj plaws ntawm ib feeb, vim qhov no yuav ntxhov siab lub tshuab thiab txo nws lub neej.

7. Khaws lub cav tu: Tswj lub npe saib xyuas cov kev ua ub no, suav nrog kev ntxuav, thiab hloov chaw. Cov ntaub ntawv no tuaj yeem pab ntsuas lub tshuab kev txij nkawm thiab txheeb xyuas cov teeb meem rov muaj dua lossis cov qauv. Txheeb xyuas cov cav tsis tu ncua kom ntseeg tau tias kev tswj xyuas kev ua haujlwm tau ua raws li tau npaj tseg.

Hauv kev xaus, kev saib xyuas tsis tu ncua yog qhov tseem ceeb rau kev ua tau zoo thiab ntev ntawm koj lub tshuab nqus thermoforming ntim tshuab. Los ntawm kev ua raws cov lus qhia txij nkawm, koj tuaj yeem khaws koj cov tshuab khiav kom zoo, txo qis dua thiab ua lag luam zoo ntim. Nco ntsoov los tham txog cov chaw tsim khoom ntawm lub khw Mooj Qhia txog cov lus qhia txog kev kho kom zoo, thiab ib txwm ua kom muaj kev nyab xeeb ib qho tseem ceeb thaum siv cov tshuab no.

Lub sij hawm Post: Jun-29-2023