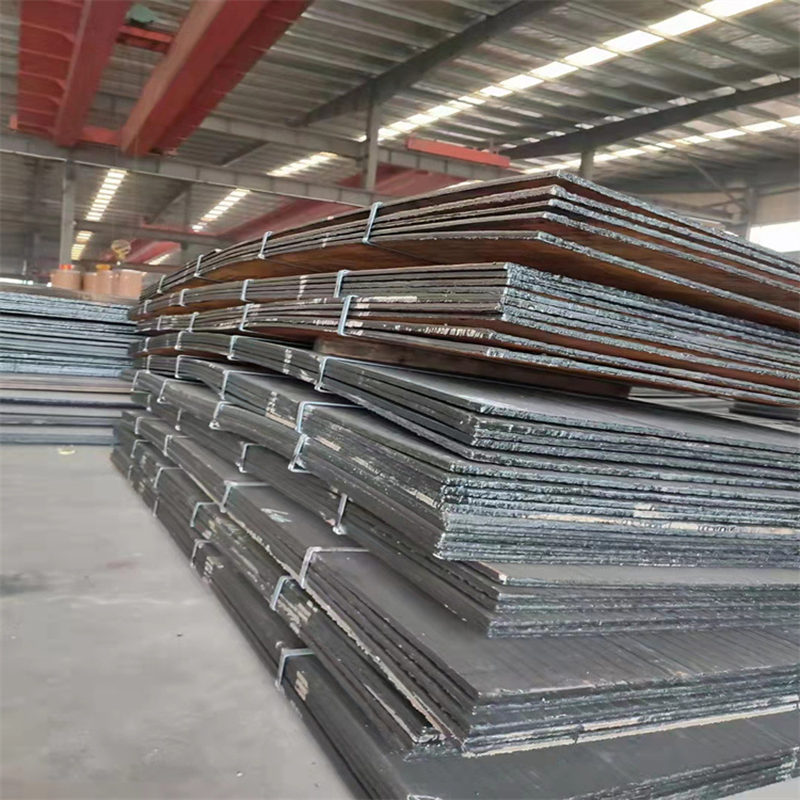

1. Hnav-Resistant Steel Phaj Txheej txheem cej luam

Hnav cov tiv thaiv steel phaj, namely hnav-resistant steel phaj, yog cov khoom tshwj xeeb tshwj xeeb siv nyob hauv thaj chaw ua haujlwm. Nws yog tsim ntawm cov roj carbon hlau tsis muaj roj thiab aluminium hnav-resistant txheej.

Cov ris tsho-resistant steel phaj muaj cov yam ntxwv ntawm lub zog siab thiab lub txiaj ntsig zoo tiv thaiv. Lub alloy hnav-resistant txheej yog feem ntau 1/3 txog 1/2 ntawm tag nrho cov tuab. Thaum nyob hauv kev ua haujlwm, lub matrix muab kev kawm zoo xws li muaj zog, thiab lub meej mom los tiv thaiv sab nraud muab kom tau raws li cov cai ntawm kev ua haujlwm ntawm kev ua haujlwm.

Muaj ntau hom kev hnav-resistant steel daim hlau, suav nrog composite hnav-resistant steel daim hlau thiab alloy quenched hnav-reseness gold daim hlau. Piv txwv, KN60 Cov hnav-resistant steel phaj yog ib hom khoom tsim los ntawm Alloy Cov Khaub Ncaws Quality lossis cov hlau tsis muaj zog qis thiab cov yas ntawm txoj kev surfacing. Lub tshuab ntsuas ntawm KN60 Res resistant steel phaj muaj raws li hauv qab no: Vickers Hardness yog 1700HV; Cov khoom siv tsawg-cov roj carbon steel, thiab lwm hom surfacing nyuaj alloys thiab Niobium carbide tuaj yeem muab raws li cov tseev kom muaj. Lub chromium thiab boron alloat carbides yog nplua nuj; Lub hardness ntawm cov composite hnav-resistant txheej yog C62-65 HRC; Lub thickness yog 3 - 15 millimeters; Cov ntsiab lus nyuaj cov ntsiab lus yog ntau tshaj 50%; Qhov siab tshaj plaws ua haujlwm kub yog 1000 ° C.

Ib qho ntxiv, hnav-resistant steel phaj 360 kuj yog ib hom kev muaj zog thiab hnav muaj zog-resistant hnav phaj. Nws yog tsim los ntawm cov thev naus laus zis prestressing thiab muaj cov zog zoo dua thiab lub zog compressive, nrog rau kev coj ua zoo thiab kev cuam tshuam tsis kam.

2. Kev siv ntawm cov ris-resistant steel daim hlau

2.1 Kev Siv Ntau Yam

Hnav-resistant steel daim hlau pom cov ntawv thov dav dav hauv ntau yam kev lag luam. Hauv kev lag luam metallurgical, lawv tau siv nyob rau hauv cov khoom siv xws li crushers thiab conveyor siv tawv, uas tau tas mus li tsis tu ncua thiab cuam tshuam. Nyob rau hauv cov thee kev lag luam, lawv tau ua haujlwm hauv Ultution thiab tsuas Machinery qhov chaw los tiv thaiv lub qhov hnyav hnav. Txoj kev lag luam Maas ua rau kev siv cov khoom siv-tiv taus steel hauv thiab cov milling kom ntseeg tau lub neej kev pabcuam ntev. Nyob rau hauv lub zog kev lag luam, lawv tau siv nyob rau hauv cov pulverizers thee thiab cov hmoov tshauv coling.

Piv txwv li, hnav cov hlau tiv taus steel 360 tau siv dav hauv cov liaj teb xws li tsheb, tshuab hluav taws xob, hluav taws xob, hluav taws xob, cov khoom siv hluav taws xob, thiab kev tsim kho. Nws yog qhov zoo tagnrho rau cov khoom siv uas tsis tshua muaj cuam tshuam loj heev hauv kev lag luam machinery vim nws cov kev tsis kam, thiab corrosion tsis kam.

2.2 Cov nqi siab-ua hauj lwm siab

Piv nrog rau lwm cov ntaub ntawv, hnav-resistant steel daim hlau muab kev ua tau zoo. Txawm hais tias tus nqi pib ntawm cov khaub ncaws-tiv taus steel phiaj yuav yog siab me ntsis siab dua li qee cov ntaub ntawv ib txwm muaj thiab kav ntev rau hauv kev txuag nyiaj ntev. Piv txwv li, ib lub tuam txhab uas siv cov roj uas tiv thaiv cov hlau tiv thaiv nws cov kauj ruam ntau yuav pom tau txo qis thiab hloov cov khoom lag luam ntxiv thiab cov nqi txuag tau.

Raws li cov ntaub ntawv, cov kev pabcuam lub neej ntawm kev hnav cov hlau tiv taus hlau feem ntau ntau zaus ntev dua li cov phiaj hlau dog dig. Qhov no txhais tau tias cov tuam txhab tuaj yeem txo lawv cov nqi thiab cov nuj nqis txij nkawm raws sijhawm. Tsis tas li ntawd, kev ua tau zoo ntawm cov ris-tiv taus steel daim hlau txo qhov kev pheej hmoo ntawm cov khoom siv tsis ua hauj lwm thiab ntau lawm qeeb, ntxiv txhim kho lawv cov txiaj ntsig kev khwv nyiaj txiag. Raws li qhov tshwm sim, ntau thiab ntau ntau yam lag luam thiab cov tuam ntxhab tab tom qhia txog kev nyiam rau cov khoom siv-tiv taus-tiv taus cov hlau uas tiv taus cov hlau.

3. Cov khoom siv ntawm kev tso tawm ntawm cov ris-resisthant hlau phiaj hlau

3.1 Hom Khoom Siv Khoom Siv

Hnav cov hlau tiv thaiv steel hlau feem ntau yog ua los ntawm Surfacing Alloy Hnav-resisthat cov khaubncaws sab nraud povtseg ntawm cov roj carbon steel lossis cov hlau qis. Tseem muaj cov ntaub thaiv cov hlau uas tiv thaiv cov hlau thiab cov hlau txiav tawm-cov hlau tiv thaiv steel phiaj. Piv txwv li, cov tshuaj sib xyaw cov ris-resistant steel phaj yog tsim los ntawm kev sib txuas ntawm alloy hnav-resistant txheej nrog siab heev thiab hnav zoo heev ntawm cov kav hlau.

3.2 Ntau hom ntawm cov yam ntxwv

Muaj ntau ntau yam ntawm cov hnav-resistant steel daim hlau: dav dav hom, kev cuam tshuam-resistant hom, thiab siab-kub tiv taus hom.

Qhov dav dav-lub hom phiaj hnav-resistant steel phaj muaj kev ua tau ruaj khov thiab haum rau cov kev hnav dav dav. Nws muaj zoo coj tsis kam thiab muaj zog nruab nrab. Cov lus qhia kev ua haujlwm yuav suav nrog qhov nyuaj rau theem, feem ntau nyob ib ncig ntawm 50-60 hrc. Cov ntaub ntawv sib xyaw feem ntau muaj cov ntsiab lus xws li chromium thiab manganese los txhim kho cov coj kev tiv thaiv. Hauv kev ua tau zoo, nws tuaj yeem tiv taus ib co lej ntawm kev puas tsuaj ntawm kev puas tsuaj thiab yog siv dav hauv kev lag luam xws li machinery raug.

Qhov cuam tshuam-resistant hnav-resistant steel phaj yog tsim los tiv thaiv hnyav hnyav. Nws muaj siab heev thiab kev cuam tshuam zoo heev. Cov khoom siv feem ntau muaj cov ntsiab lus alloy uas txhim kho nws cov kev cuam tshuam tsis kam. Piv txwv li, qee qhov cuam tshuam-tiv taus-tiv taus steel daim hlau yuav muaj lub hardness ntawm ib puag ncig 45-55 hrc tab sis nrog kev cuam tshuam zoo dua. Hom no yog qhov tsim nyog rau kev thov uas cov cuab yeej cuam tshuam rau cov khoom siv ntau zaus, xws li hauv kev lag luam mining thiab kev tsim kho.

Lub siab-kub tiv thaiv cov ris-resistant steel phaj tuaj yeem tiv taus ntau qhov kub. Nws yog ua los ntawm cov ntaub ntawv tshwj xeeb uas tuaj yeem tswj ruaj khov ntawm qhov kub. Cov kev ntsuas kev ua haujlwm yuav suav nrog kev ua haujlwm ntau tshaj plaws txog li 800-1200 ° C. Cov ntaub ntawv sib xyaw feem ntau muaj cov ntsiab lus xws li npib tsib xee thiab chromium kom ntseeg tau siab-kub tsis kam. Hauv kev ua tau zoo, nws yog dav siv nyob rau hauv cov kev kub-ib puag ncig xws li Furnaces thiab kilns hauv cov lag luam metallurgical thiab Maas.

Lub Sijhawm Post: Oct-31-2024